Anweisungen fuer Gutachter: Unterschied zwischen den Versionen

| Zeile 1: | Zeile 1: | ||

[[de:Anweisungen_fuer_Gutachter]] | |||

[[es:Instrucciones_para_los_Revisores]] | |||

__TOC__ | __TOC__ | ||

The [[Certification platform#reviewers|Reviewers]] have the task to technically analyse all the Project documentation, for which, they must have gone through the [[#sing-up|registration process]] in the same way as for the [[Certification platform#applicant|Applicant]]. It must also have the role of ''certification_reviewer'', as indicated in [[#reviewers-designation|Reviewer designation]]. | |||

Each [[Certification platform#reviewers|Reviewer]] must comply with the aspects mentioned below: | |||

== | == Analysis of Technical Documentation == | ||

=== | === Points to be verified by the Reviewer 1: === | ||

==== | ==== completeness ==== | ||

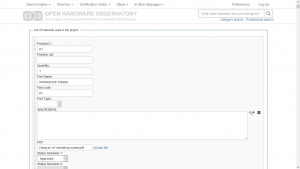

[[ | [[File:Inst-review1.jpg|thumb]] | ||

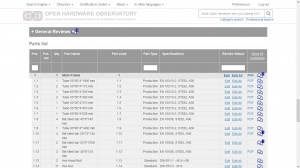

[[ | [[File:Inst-review2.jpg|thumb]] | ||

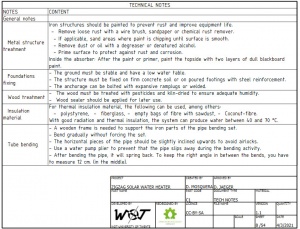

[[ | [[File:Tech-notes.jpg|thumb]] | ||

Checks if all required documents have been submitted | |||

* | * Mandatory documents for all projects | ||

** | ** Bill of materials | ||

** | ** Drawings of all production parts | ||

** | ** Assembly instructions | ||

* | * Optional documents: Technical notes | ||

** | ** General technical notes: tolerances, surface treatments, special materials, manufacturing processes, surface quality... | ||

** | ** Standards and references | ||

** | ** Hydraulic scheme | ||

** | ** Electrical plan | ||

** | ** Printed circuit board (PCB) | ||

** Software | ** Software | ||

** | ** Programmable logic controller (PLC) | ||

** | ** Civil engineering | ||

** | ** Structure analisis | ||

** | ** Others that are considered necessary | ||

* | * Missing documents are requested from the applicant | ||

==== Review of the submitted documents ==== | |||

Checks if the information in the submitted documents is complete and correct | |||

* Bill of materials | |||

** Are all parts and assemblies covered? | |||

** Are all quantities correct? | |||

** Are all required material specifications available? | |||

** Are all specifications for purchased parts and standard parts complete? | |||

** Are the part code and sheet fields well numbered? | |||

** Are all the Part Names correct? | |||

* Technical drawings | |||

** Are all the pieces drawn? | |||

** Are all the required views available? | |||

** Are all required dimensional data available? | |||

** Are all the necessary information for manufacturing? | |||

** Are the views well scaled? | |||

** Is the information in Part type correct? | |||

* Technical notes | |||

** Are the technical notes consistent with the project? | |||

** Do the technical notes provide useful information? | |||

** Are the technical notes consistent with the concept of Open Hardware? | |||

* > All annotations are uploaded on the certification page | |||

* > The applicant must answer or clarify each point | |||

==== Suggestions for improvement ==== | |||

* Serious errors (for example in terms of safety, longevity, quality of the work process etc.): the applicant must check the suggestions, clarify them with the reviewer if necessary and prepare proposals for improvement | |||

* Less serious errors (for example, use of other parts, improve the operation increase energy efficiency, etc.): no need for action, can be used later in an optimized version of the project (fork) | |||

=== | === Only then does Reviewer 2 proceed === | ||

* Begins only when the Reviewer 1 has finished his work and the Applicant has clarified all open points with Reviewer 1. | |||

* | * Checks the entire project for completeness, correctness and opportunities for improvement | ||

* | * > All annotations are uploaded on the certification page | ||

* | * > The applicant must answer or clarify each point | ||

* > | |||

This process is repeated as many times as Reviewers are assigned to the Project. | |||

<div id="non-conf"></div> | |||

> | |||

== | == Release of non-conformities == | ||

[[ | [[File:Project comments.JPG|thumb|<small>'''Comments in a project'''</small>]] | ||

[[ | [[File:Project action required.JPG|thumb|<small>'''Item marked as ''Action required'''''</small>]] | ||

On the [[#project_page|project page]], comments on technical aspects can be made, these comments are the channel in which non-conformities are issued. | |||

A comment or non-conformity must be issued in the following cases: | |||

* | * Information is missing in order to be able to classify or recognise a part or assembly. | ||

* | * Information about a supplier is missing (links to websites tend to be modified). | ||

* | * Missing information on a purchased part, in order to be able to locate it in current markets. | ||

* | * Missing measurements or other specifications in the [[Technical drawings]]. | ||

* | * Lack of coherence in the specifications, with respect to the assembly of the parts. | ||

* | * Missing fields in the [[#part_list|Parts list]]. | ||

* | * Depending on the type of assembly: | ||

** | ** There must exist for each part, a [[Technical drawings|plan in PDF]] and its respective [[CAD files|CAD file]] (the latter, with the purpose of being able to review the 3D information in other CAD systems different from the one that has generated the parts). | ||

** 3D | ** The 3D printing parts must be accompanied by their STL file, in addition to their [[Technical drawings|PDF drawing]] and their [[CAD files|CAD file]]. | ||

** | ** For printed circuit boards (PCB), the addresses of their components must be included. | ||

* | * In case of confusing information or obvious mistakes, a friendly comment should be left, pointing out the mistake in the corresponding item. | ||

* | * In case of problems regarding the Project in general, there is an extra field in the [[#part_list|Parts list]], where comments can be added | ||

* | * Those items that require some correction by the [[Certification platform#applicant|Applicant]], must be marked as ''Action required'', in the [[#project_page|Project page]], action ''Edit'', tab ''Part list''. | ||

* | * This process can be repeated as long as there are comments or non-conformities with corrections to be made and not all the items of the [[#part_list|Part list]] are approved, through which, communication with the [[Certification platform#applicant|Applicant]] must always be maintained. | ||

== Project Approval == | |||

= | [[File:Project aproved.JPG|thumb|<small>'''Item marked as ''Approved'''''</small>]] | ||

[[ | After all non-conformities have been resolved, you should: | ||

* Mark each item in the [[#part_list|Part list]] as ''Approved'', on the [[#project_page|Project page]], action ''Edit'', tab ''Part list''. | |||

* | * Add a final comment including ''OK, FINISHED''. | ||

* | * Notify the [[Certification platform#coordinator|Coordinator]], about the Project Approval. | ||

* | |||

Version vom 6. Dezember 2021, 01:30 Uhr

The Reviewers have the task to technically analyse all the Project documentation, for which, they must have gone through the registration process in the same way as for the Applicant. It must also have the role of certification_reviewer, as indicated in Reviewer designation.

Each Reviewer must comply with the aspects mentioned below:

Analysis of Technical Documentation

Points to be verified by the Reviewer 1:

completeness

Checks if all required documents have been submitted

- Mandatory documents for all projects

- Bill of materials

- Drawings of all production parts

- Assembly instructions

- Optional documents: Technical notes

- General technical notes: tolerances, surface treatments, special materials, manufacturing processes, surface quality...

- Standards and references

- Hydraulic scheme

- Electrical plan

- Printed circuit board (PCB)

- Software

- Programmable logic controller (PLC)

- Civil engineering

- Structure analisis

- Others that are considered necessary

- Missing documents are requested from the applicant

Review of the submitted documents

Checks if the information in the submitted documents is complete and correct

- Bill of materials

- Are all parts and assemblies covered?

- Are all quantities correct?

- Are all required material specifications available?

- Are all specifications for purchased parts and standard parts complete?

- Are the part code and sheet fields well numbered?

- Are all the Part Names correct?

- Technical drawings

- Are all the pieces drawn?

- Are all the required views available?

- Are all required dimensional data available?

- Are all the necessary information for manufacturing?

- Are the views well scaled?

- Is the information in Part type correct?

- Technical notes

- Are the technical notes consistent with the project?

- Do the technical notes provide useful information?

- Are the technical notes consistent with the concept of Open Hardware?

- > All annotations are uploaded on the certification page

- > The applicant must answer or clarify each point

Suggestions for improvement

- Serious errors (for example in terms of safety, longevity, quality of the work process etc.): the applicant must check the suggestions, clarify them with the reviewer if necessary and prepare proposals for improvement

- Less serious errors (for example, use of other parts, improve the operation increase energy efficiency, etc.): no need for action, can be used later in an optimized version of the project (fork)

Only then does Reviewer 2 proceed

- Begins only when the Reviewer 1 has finished his work and the Applicant has clarified all open points with Reviewer 1.

- Checks the entire project for completeness, correctness and opportunities for improvement

- > All annotations are uploaded on the certification page

- > The applicant must answer or clarify each point

This process is repeated as many times as Reviewers are assigned to the Project.

Release of non-conformities

On the project page, comments on technical aspects can be made, these comments are the channel in which non-conformities are issued.

A comment or non-conformity must be issued in the following cases:

- Information is missing in order to be able to classify or recognise a part or assembly.

- Information about a supplier is missing (links to websites tend to be modified).

- Missing information on a purchased part, in order to be able to locate it in current markets.

- Missing measurements or other specifications in the Technical drawings.

- Lack of coherence in the specifications, with respect to the assembly of the parts.

- Missing fields in the Parts list.

- Depending on the type of assembly:

- There must exist for each part, a plan in PDF and its respective CAD file (the latter, with the purpose of being able to review the 3D information in other CAD systems different from the one that has generated the parts).

- The 3D printing parts must be accompanied by their STL file, in addition to their PDF drawing and their CAD file.

- For printed circuit boards (PCB), the addresses of their components must be included.

- In case of confusing information or obvious mistakes, a friendly comment should be left, pointing out the mistake in the corresponding item.

- In case of problems regarding the Project in general, there is an extra field in the Parts list, where comments can be added

- Those items that require some correction by the Applicant, must be marked as Action required, in the Project page, action Edit, tab Part list.

- This process can be repeated as long as there are comments or non-conformities with corrections to be made and not all the items of the Part list are approved, through which, communication with the Applicant must always be maintained.

Project Approval

After all non-conformities have been resolved, you should:

- Mark each item in the Part list as Approved, on the Project page, action Edit, tab Part list.

- Add a final comment including OK, FINISHED.

- Notify the Coordinator, about the Project Approval.